- Product group:

- Kaivosteollisuuden laitteet ja palvelut

CiDRA Minerals Processing Inc.

- Booth:

- 515

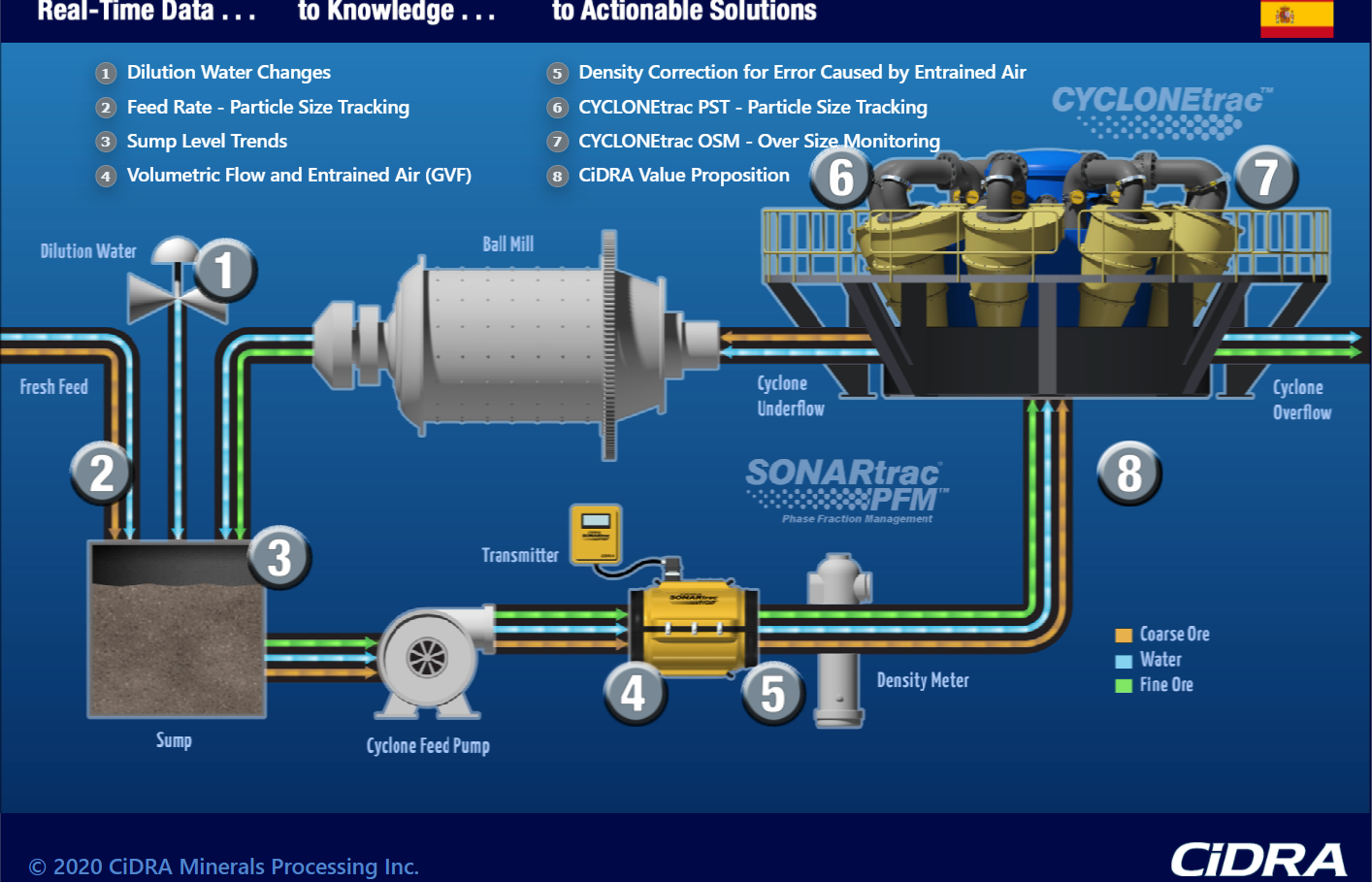

Combining the power of the SONARtrac VF/GVF dual measurement system with PFM and CiDRA’s CYCLONEtrac Particle Size Tracking System (PST), which provides real-time particle size measurement of each cyclone, there is finally an integration of technologies that truly enables the Transformation of data, to knowledge, to action, thereby providing the ability to optimize recovery, throughput and net metal production

The CYCLONEtrac Particle Size Tracking (PST) system is a novel system that provides real-time feedback of grind circuit and individual hydrocyclone performance. The technology’s value lies in its ability to track the particle size of the entire overflow stream from a hydrocyclone battery based on the contribution from each individual hydrocyclone. This enables real-time closed-circuit grind control strategies targeting improved Mineral recovery, increased grind efficiency, while maintaining or increasing plant throughput.

System Features:

- Tracks Key Parameters of Grind Performance (passing or retained on screen, eg %+150um)

- Remote Monitoring Capability

- Minimal Hydrocyclone Downtime for Installation and Maintenance

- One Time Calibration

Plant Benefits:

- Enables Real-Time Closed Grind Circuit Control

- Individual Cyclone Monitoring

- Enables Improved Recovery Without Loss of Throughput

CYCLONEtrac PST Installation

CIDRA’s patented SONARtrac , non-contact technology provides dual measurement Capability of the volumetric flow and air content (gas void fraction (GVF) in slurries and liquids. This unique combination finally enables true phase fraction management leading to unprecedented improvement in process efficiencies and operations.

Whether used to correct total volumetric flow in bubbly flows, Correcting the measurement error in density meters for a more accurate mass balance or for detecting the cause of process flow upsets, SONARtrac PFM delivers both top and bottom line value for thousands of customers around the world .

Entirely non-contact, full bore clamp-on design enables:

- Installation without process shutdown

- No pressure drop

- No potential for leaks

- No wetted parts to corrode or fail

- No flow obstruction, no clogging

- No moving parts

Typical SONARtrac installation

SONARtrac Installation